Fast Set-up

Fast Set-up Presses accept die sets with 1, 2 or 3 moving platens and produce parts with up to 4 lower and 2 upper levels. Features include computer control over critical part functions and fast setup capabilities with a removable die set.

Programmable Feeder System

CINCINNATI has been the leader in development of programmable controlled powder feeder systems. Operators have complete control over all critical powder feed shoe motions though the Press Control Center combined with an AC servo motor driven ball screw feeder drive. Good parts begin with consistent filling of the die cavity. The Fast Set-Up Programmable Feeder combination allows optimized part quality at the high production rates needed to be competitive now and in the future.

Multi-Level Capability

With available options, Fast Set-Up Presses can be configured to produce multi-level parts using the following independently controlled part making tool levels: Inner Upper Punch, Outer Upper Punch, Shelf Die or Straight die, Middle Platen Punch, Bottom Platen Punch, Stationary Punch, and Through, Stepped or Blind Core Rod.

CINCINNATI® follows the policy of continuous advancement in product development. For this reason, specifications and dimensions are for reference only and can change without notice. Foundation plans are furnished with each new machine installation.

| Features | 66-DC-4.5 | 110-DC-4.5 | 220-DC-4.5 |

|---|---|---|---|

| Die Set |  |

|

|

| Main Ram Pressing (tons) | 66 | 110 | 220 |

| Productivity (SPM) | 12-34 | 12-30 | 10-30 |

| # Of Pressing Levels Upper* | 2 | 2 | 2 |

| # Of Pressing Levels Lower* | 4 | 4 | 4 |

| Fill Depth (in) | 4.5 | 6 | 6 |

| Die Opening (in) | 7-9/16 | 8-9/16 | 10-1/2 |

| Platen Ejection Capacity (tons) | 33 | 50 | 100 |

| Core Rod Ejection Capacity (tons) | 6 | 6 | 6 |

| Feeder Opening (in) * | 3-1/4 | 3-1/4 | 4-1/2 |

| Main Ram Tonnage Monitoring |  |

|

|

| SPC Data Collection |  |

|

|

| Main Ram Tonnage Monitor |  |

|

|

| Programmable Feeder |  |

|

|

| Powder Hopper(s) |  |

|

|

| Top Punch Holddown |  |

|

|

| Allen Bradley Control |  |

|

|

| Touchscreen HMI |  |

|

|

| Remote Diagnostics |  |

|

|

| Machine Commissioning & Training |  |

|

|

*Options May be Required

Key Features

-

Mechanical Press

Mechanical presses are famous for their high production rates and part making accuracy. The all steel welded construction uses a tie rod design to provide a rigid robust press structure required for precision part production. An AC Variable Frequency main drive motor provides power to double reduction gearing contained in a fully enclosed crown located above the die area to keep powder out of critical drive mechanisms. All drive mechanisms are lubricated through a double filtered pressurized recirculation oil system to ensure long reliable service under demanding conditions.

-

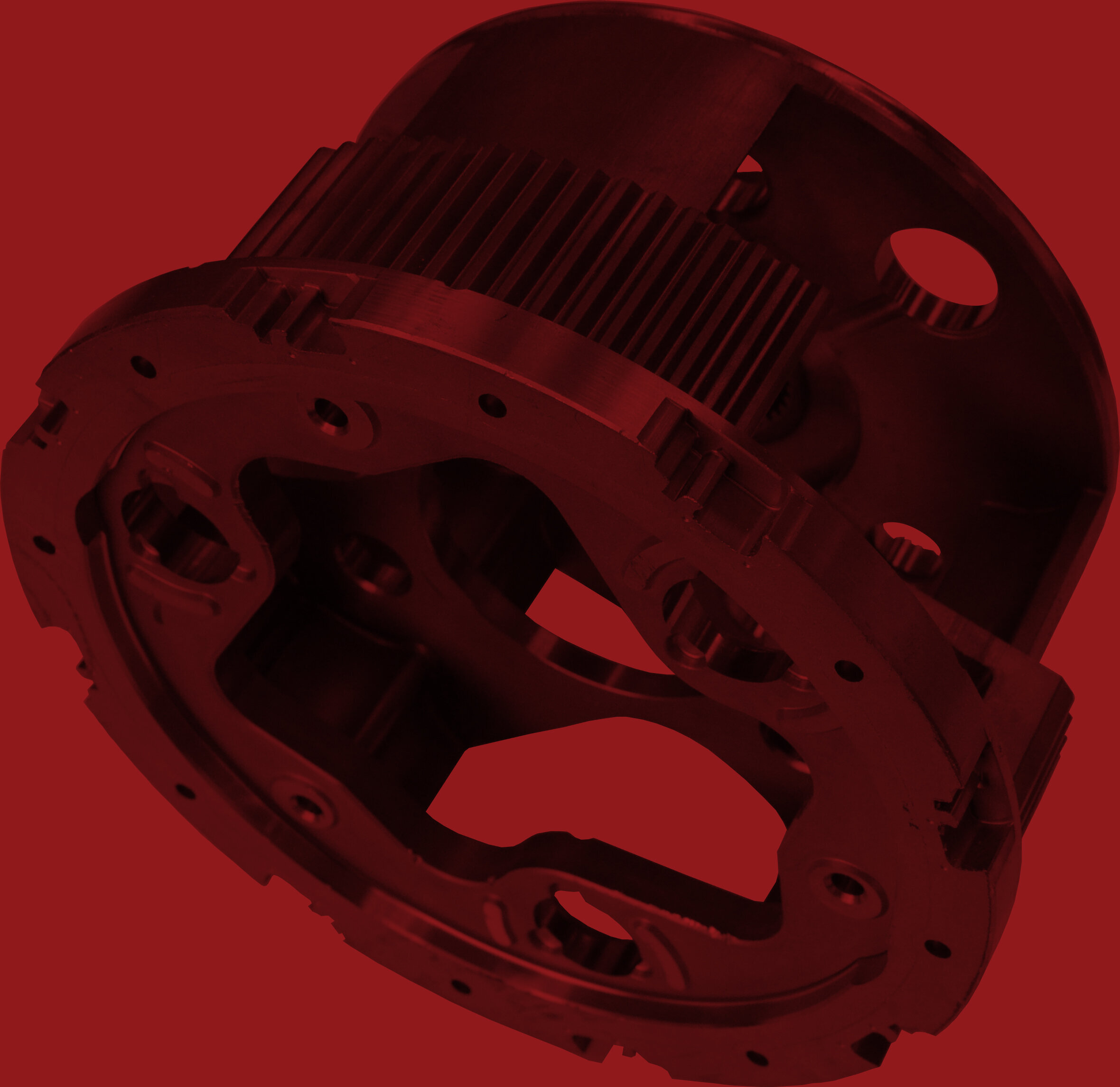

Removable Die Set

The press frame is designed to accept a removable Die Set. A unique air caster system moves die sets between the press and a Simulator that is used to facilitate tooling installation outside the press. This minimizes part-to-part changeover times by allowing timely tool changes to be performed off-line while the press continues to produce parts using a second die set. The press frame can be configured to accept die sets with 1, 2 or 3 moving platens to provide for maximum system versatility.

-

Withdrawal Press Motion

Withdrawal press motion permits start of the fill function earlier in the press cycle than other types of press motion. It also reduces potential for air entrapment and causes the least disruption of the powder during entry into the die cavity. This optimizes the press cycle and helps ensure production of high quality consistent parts.

-

CINCINNATI Press Control Center

Fingertip programmable computer control of press functions is provided by the Press Control Center designed and built by CINCINNATI. The combination of Menu Driven Software and Softkey Technology simplify set-up and operation to reduce operator effort and ensure proper production of repeat production lots.

-

Precision Common Guiding

Absolute guiding is achieved for Top Punch Plate and Die Platen through the use of common guiding. With absolute platen alignment, tooling lasts longer, maintenance is minimized and higher quality precision parts can be produced.

-

Extensive Support Services

CINCINNATI provides an extensive list of comprehensive support services with each new press to ensure many years of productive profitable service.