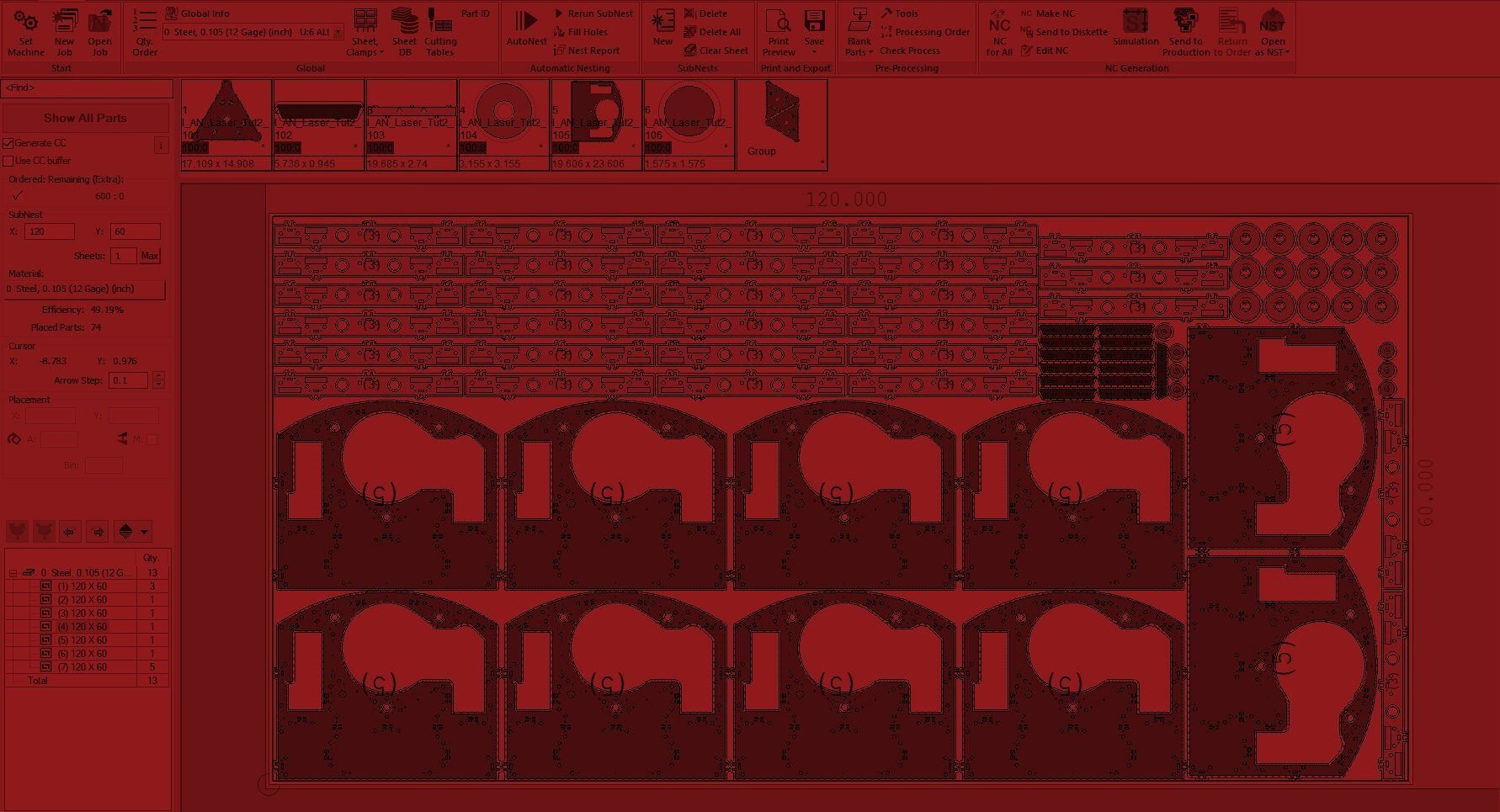

Amplify your ability to nest your laser parts with software automation, and create optimized machine code to make your Cincinnati laser (and most other lasers) operate at top performance

Nesting PRO

Automate your ability to create enhanced nests by applying unique rules-based features that are used only when needed. Further increase your programming productivity with batch conversion of flats or 3D models--automatically unfolding them to the proper blank size with folding data based on your unique operation. Finally, do the ultimate by programming and nesting your new CI Laser (and most other lasers) automatically...via our optional ERP interface.

Windows 10 (not Home version) PC Computer, 3GHz Processor, 64 bit required

Full 64 bit Microsoft Office

Video resolution 1920 x 1080, NVIDIA Quadro (recommended)

500 GB available on hard drive

20 GB RAM

USB Port

Microsoft Windows networking (for optional network license)

Key Features

One(1) seat of Nesting PRO software and one(1) post processor for a Cincinnati laser

Flat file import (DXF, DWG) and 3D file import (SLDPRT, STEP, SAT, IGS, X_T)

2D CAD flat creation and editing

Automatic true shape part nesting for optimal material utilization

Selectable time limitation for nesting

Advanced Common line cutting

Fly cutting routines

Rules-based tabbing (wire joints)

Rules-based slug cut up

Basic material inventory management

Estimating and Quoting Package

Creates tasks for laser automation (CI March System)