Shear Control Retrofit

The Cincinnati Touchscreen Shear Control (TSC) provides fast, repeatable machine setup and gage positioning for productive shearing and accurate blanks. Combining the machine and gage controls into one convenient location simplifies machine operation.

Features

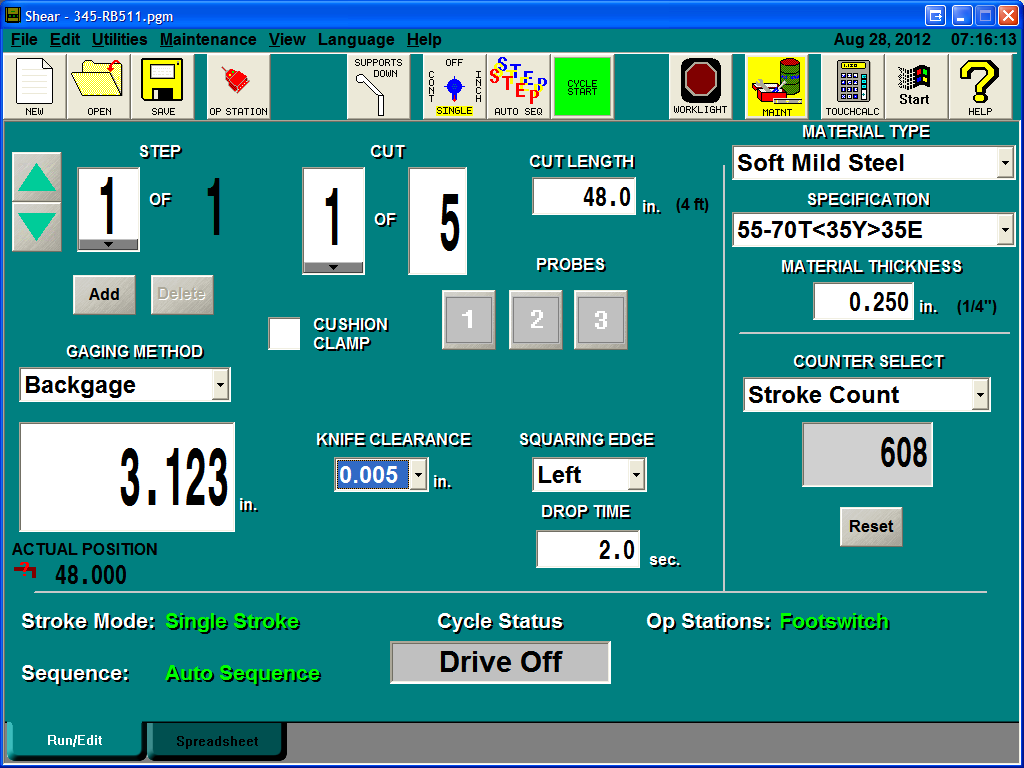

Customize Your Job

The operator enters the desired number of steps, number of cuts, gage position, material thickness, material type and specification. The TSC positions the gage, commands the proper rake angle and displays the recommended knife clearance to achieve the best edge and flattest blank.

Fast Setup

To produce blanks with minimal burr and distortion, material type and thickness combinations require different shear settings. The control software references preloaded rake and knife clearance parameters stored in the Material Library for the specified material. This assures the shear is setup with optimum machine settings. Additional settings can be input by the user to satisfy specialized shearing applications.

Increased Accuracy

Blank dimensions are accurately held by a precision heavy-duty backgage. Gage positions can be entered as decimal or fractions. Multi-axis gaging is optionally available combining the use of the backgage with a programmable front gage to increase productivity and accuracy when squaring, stripping or blanking large sheets.

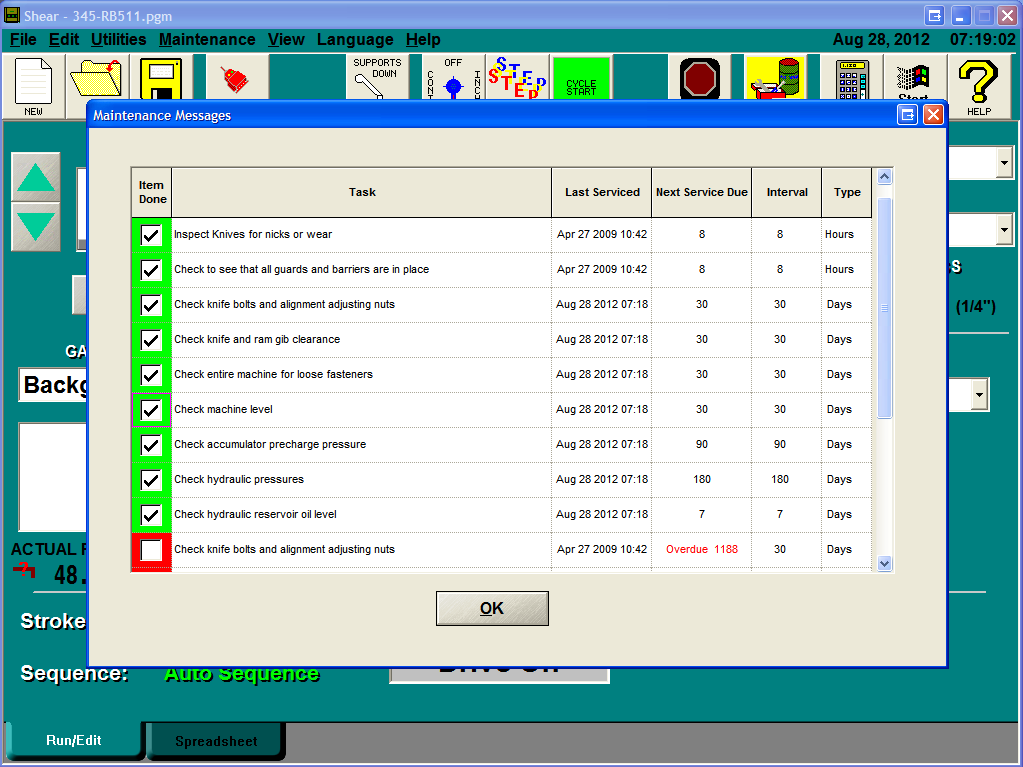

Auto-Advancing Controls

The shear can be cycled in either single-step or automatic mode with a shearing sequence of up to 99 steps. The control displays the gage position and remaining number of cuts, while automatically advancing to the next step. Optional probes in the backgage angle allow the shear to be cycled without a footswitch. Probes reduce operator fatigue and improve accuracy by assuring the material is correctly positioned against the backgage.

Installation Includes

Windows 10 Operating System

PC-Based Control

Flash Drive

22" LCD Display with Touchscreen Interface

Ethernet Communication Port

Stroke and Batch Counters

Machine Diagnostics