Meet the Swiss Army Knife of Fiber Lasers

The CL-900 packs 8kW laser power into just 4kW. Here’s how.

“Any sufficiently advanced technology is indistinguishable from magic.” —Arthur C. Clarke

If you were to walk by the CL-900 Series Fiber Laser Cutting System with Corona™ laser technology, you would be forgiven if you didn’t stop in your tracks. On the outside, it looks much like other fiber lasers. But if you were aware of the variable beam technology contained within, it just might make you do a double take. It’s pretty darn close to magic.

Built by our partners at nLIGHT® (a global leader in fiber laser technology), the Corona’s groundbreaking innovation is its programmable all-fiber beam quality. The result is what makes the CL-900 so special: optimized machine tool performance across various metals and thicknesses.

The old way: free-space optics, multiple machines, added cost

Traditionally, steering of the laser beam is done with a set of free-space optics. Contamination sources, a reduced beam brilliance and added mechanical complexity all become nuisances significant enough to require multiple machines for multiple metals and thicknesses.

That’s because beam characteristics matter. The size and shape of the spot, the rate of divergence, the distribution of intensity—all of it factors in. Technology that’s been touted recently, called Zoom, changes beam diameter by moving two free-space optics closer together or farther apart. But that has inherent issues as well. Because the energy is not being distributed (it’s merely being made bigger or smaller), a lot of energy is wasted. That’s why companies relying on Zoom need bigger, higher output lasers to get the job done.

The good news: The CL-900’s Corona technology allows for quality cutting with a 4kW laser. By using a 4kW rather than a 6kW or 8kW, you’re saving money on the front end and enjoying a significantly longer life span. Bottom line: It’s never been easy to simply and efficiently change the beam quality for different applications. But now, with the Corona, it is.

The new way: one variable beam fiber laser

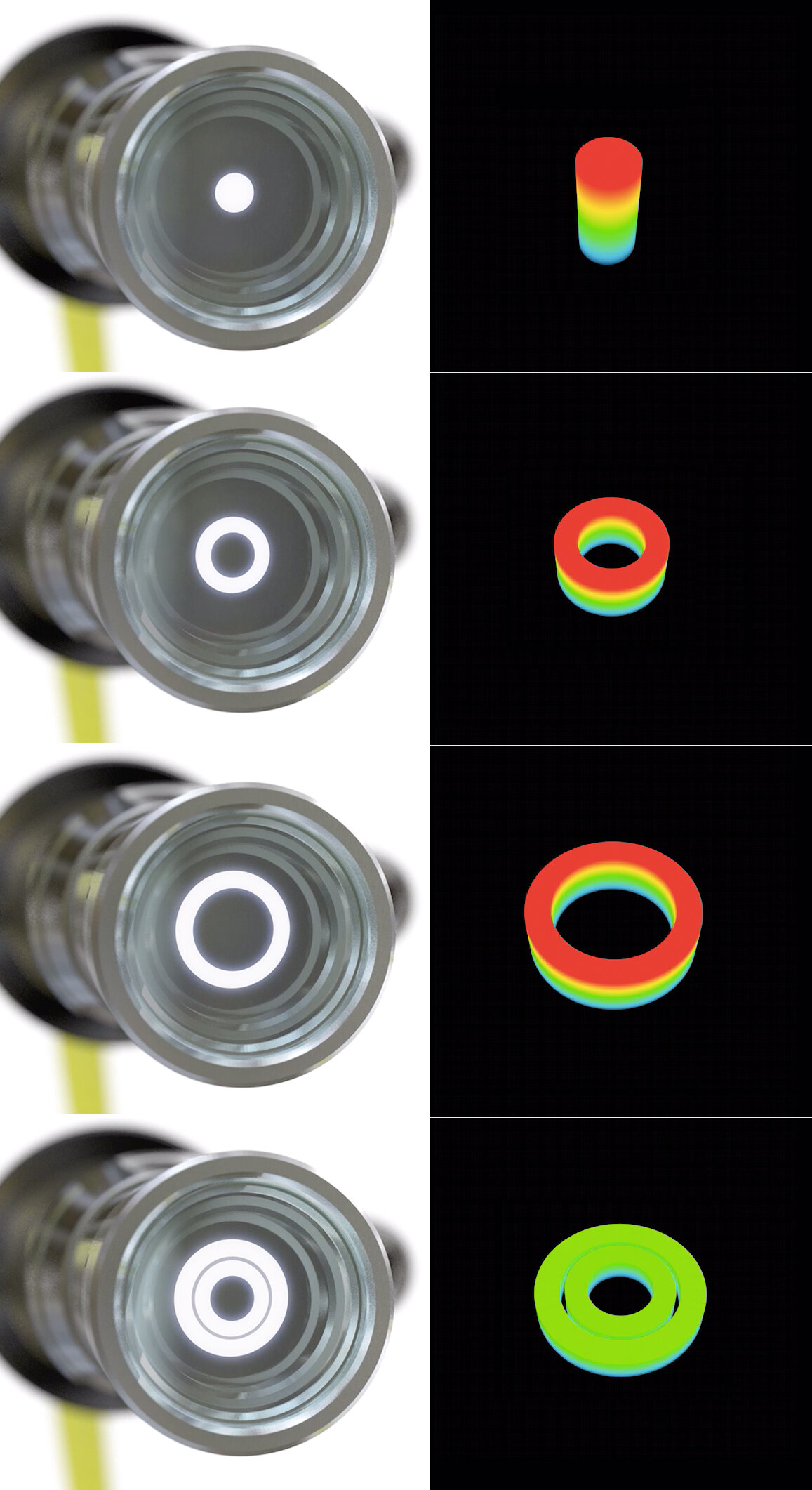

The Corona software lets users go from a high-intensity, spot-sized beam to a large, donut-shaped beam, and it’s as simple as changing the mode. This monumental leap is what allows the CL-900 to cut mild steel, stainless steel, aluminum and red metals—both thick- and thin-gauge—at a high speed and quality.

No more stationary beam profiles. No more jumping from machine to machine for thin and thick metals. Just incredible flexibility and a greater competitive advantage.

The CL-900 uses multiple output modes to configure how the laser’s energy will be allocated. The first mode is for piercing and cutting light-gauge material. As the modes increase, you’ll go up in material thickness. And again (we cannot stress enough what a game changer this is), it can all be done on the fly with the Corona.

Think of the CL-900 as a gym member, and the Corona as a skilled personal trainer.

If we break this down in the simplest possible terms, Corona technology redistributes energy more efficiently. That’s it. Just as a gym member unlocks new levels of strength and speed after being coached by a trainer, your laser cutting system will instantly enjoy leaps in speed, efficiency and productivity when cutting metals of all types and thicknesses.

“No compromises” laser cutting is finally here.

Stop purchasing multiple machine tools and compromising performance. Stop relying on complex and expensive free-space optical technologies. As it turns out, it’s so much simpler and more cost-effective than you think.