Welcome to the Newsroom

Search by Category

Unlocking Efficiency: The Power of Press Brake Automation

In the fast-paced world of metal fabrication, the pressing need for efficiency and precision has never been greater. Enter the era of press brake automation, a game-changing advancement that promises to revolutionize how you handle manufacturing processes. Imagine a future where your production lines hum along with minimal human intervention, churning out highly accurate, consistent parts at lightning speed. Automation is not just a technological upgrade; it’s a strategic advantage that can propel your business forward, reducing costs and boosting productivity.

How to Reduce Errors with Press Brake Automation Software

Discover how press brake automation software lowers errors, enhances precision, and boosts productivity with CIberDash integration.

Decoding Fiber Laser Wattages: A Comprehensive Guide

Explore the implications of different fiber laser wattages. Learn how each power level affects material cutting, speed, and industry applications to help you select the right laser for your needs.

Understanding CNC Press Brakes: Hydraulic, Mechanical, Electric, and Hybrid Differences

Explore the workings of CNC press brakes and discover the key differences between hydraulic, mechanical, electric, and hybrid models.

Maximize Your Press Brake Investment with Offline Programming

For a growing number of fabricators, regardless of size, the answer lies in offline programming. Unlike traditional at-the-machine programming, offline programming involves creating press brake bending programs on a computer, separate from the machine's physical location.

CINCINNATI, Inc. Announces Alan Oak as Incoming President & CEO

Cincinnati Incorporated (CI), a leading North American provider of built-to-order machine tools, announces that after more than four years of service, Mr. Timothy Warning will be stepping down as President & CEO effective January 1, 2025. At that time Mr. Alan Oak will assume the company’s leadership position.

Nesting Pro: Strategies to Optimize Material Utilization and Reduce Waste

Learn strategies for optimizing material use and reducing waste with Nesting Pro. Discover how to save costs and help the environment today.

Enhance Operational Visibility with CIberDash: An Essential Guide

Discover how CIberDash improves operational visibility, optimizes production, and boosts efficiency. Learn key features and benefits.

Innovate Your Cutting Process with the Advanced CLX Fiber Laser

Discover how the CLX Fiber Laser enhances precision, speed, and efficiency in your cutting processes, boosting productivity and quality.

CI Has Been Awarded Best and Brightest Companies to Work For® in the Nation '24

The Best and Brightest Companies to Work For® is proud to announce and honor the newest 2024 Best and Brightest Companies to Work For in the Nation winning companies. Only companies that distinguish themselves as having the most innovative business acuteness and human resource practices can be bestowed this honor. Considering the ten to one ratio of this program, these winning companies are truly innovative in their employee engagement execution.

America’s Most Loved Workplaces 2024

Cincinnati Incorporated is proud to announce its recognition as one of Newsweek’s Top 200 Most Loved Workplaces for 2025. This prestigious award given by Newsweek, in collaboration with Best Practice Institute, highlights companies that have fostered exceptional workplace environments, earning high marks from employee surveys for satisfaction and a commitment to trust, belonging, and respect, as well as personal and professional growth.

Exploring the Impact of Cincinnati Incorporated on U.S. Manufacturing

Discover how Cincinnati Incorporated has shaped U.S. manufacturing through innovation, quality, and industry leadership over 120 years.

Advanced Fiber Laser Technology: A Deep Dive into the CLX Series Cutting System

Discover the exceptional features of Cincinnati Incorporated's CLX Series Fiber Laser Cutting System. Explore the benefits and applications of this advanced technology.

American Owned – American Built: CINCINNATI Puts its Pride on Full Display at Fabtech 2024

Today, the company continues to offer innovative solutions to enhance the operator experience while advancing productivity. Fabtech attendees (October 15-17, 2024) looking to enhance shop floor operations can get a first-hand look at what CI has to offer at exhibit space S13085.

Industrial PC provides flexible, expandable machine control without IT intervention

Machine builder Cincinnati brings system adaptability to the forefront

Fiber laser system overcomes obsolescence with EtherCAT, PC-based control platform

To remain relevant and successful, long-established companies must honor their past without losing sight of the future. This is the approach that metal fabricating machine builder Cincinnati Inc. (CI), Harrison, Ohio, has taken since its founding in the late 1890s.

Cincinnati Incorporated Certified as a Most Loved Workplace

Cincinnati Incorporated has become certified as a Most Loved Workplace® backed by the research and analysis of Best Practice Institute (BPI). Most Loved Workplace® validation provides the most comprehensive look at workplace sentiment for organizations today.

Cincinnati Incorporated honored as a 2024 VETS Indexes 4 Star Employer

VETS Indexes is proud to announce that Cincinnati Incorporated has earned the designation of VETS Indexes 4 Star Employer in the 2024 VETS Indexes Employer Awards. The award recognizes the organization’s commitment to recruiting, hiring, retaining, developing, and supporting veterans and the military-connected community.

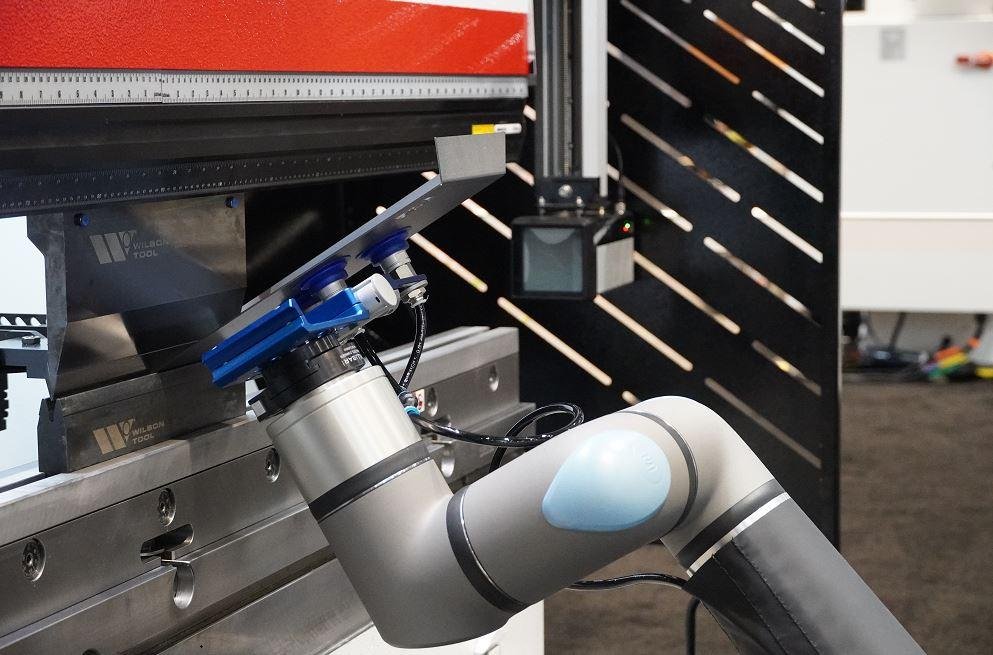

Why fabricators should get to know cobotic bending

Only a few years ago, collaborative robots, or cobots, were rolled out to demonstrate their viability in welding applications. An operator—who didn’t need to be a welder—could take the cobot, teach it by moving it along the prospective weld path, and start the welding process.

Smart Approach

One of the biggest mistakes a small to mid-size fabricator makes has nothing to do with equipment, personnel or partnerships. Rather, the error lies in dismissing automation as beyond what they need or can afford. Automation positions manufacturers for long-term success in an increasingly digital world. Reducing manual or repetitive efforts frees up skilled workers to focus on higher value tasks, minimizes errors, improves product quality and grows profitability through increased production capacity.