CI Helps Murray Equipment Bring Fabrication In-House for Better Control

Murray Equipment, based in Fort Wayne, Indiana, is an industry leader in the design, manufacture and distribution of liquid and dry handling and measuring solutions. Each market segment targeted by the company is served by a subsidiary that is branded and focused specifically on that field. President Dan Murray is the 3rd generation to take over the leadership role. His vision is to build an organization that will support customers, not only today but well into the future. Quality and on-time delivery are a large component of that concept.

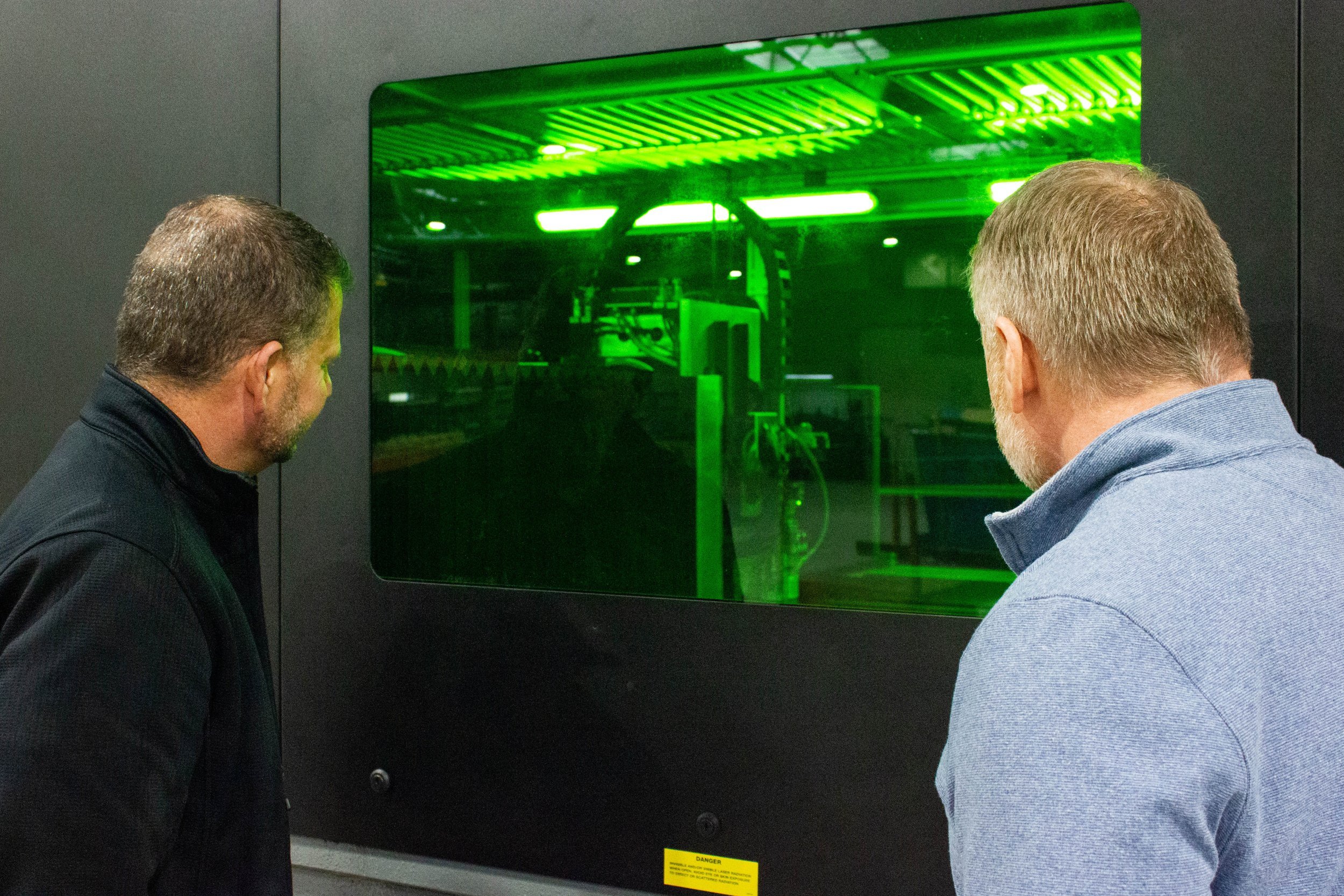

Sales Engineer, Mark Rosenberger (left) standing with President Dan Murray (right) in front of Murray Equipment’s

new 230 Ton X 12’ 230 AF-10 Press Brake

“We build custom specialized equipment, so our need is quick turnaround and small volume,” Murray said. “The problem was that we had to order a years’ worth of inventory to get components on time from the fabrication vendors we used for many of our production items.”

His solution was ambitious: develop an in-house fabrication capability that could service all the businesses in the group. A new division, Vulcan Manufacturing Systems (VMS), was created to centralize all the companies’ fabrication needs.

“We decided to expand our fabrication capabilities because of limited warehousing space and to increase our inventory turns, in addition to our desire to expand our product line with specialized tanks and hoppers.”

Big job. Big opportunities.

It was a substantial undertaking but that’s nothing new to Murray. “We have never been shy about making significant investments in R&D, facilities and quality control,” he said. “Our intention is to start making our own skids, frames, bases, etc. for the equipment we manufacture for our other brands.” Murray estimates there is around $2 million worth of work he can bring in-house.

Finding the right partner

While the company has had some fabrication capabilities for over 50 years, Murray turned to friends in the industry for advice on the best equipment currently on the market. One shop owner had just taken delivery of a new CI press brake and was enthusiastic about the results. He said that if it were possible, he would redo the whole shop floor exclusively with CI equipment.

This appealed to Murray since he wanted to work with a brand that was strong enough to be reliable and serviceable in the long term.

“I also liked the fact that CI equipment is made in the USA,” he said. “We’re supported locally, and we care about that.”

A call was placed, and CI Regional Sales Manager Mark Rosenberger came in for an evaluation.

“Mark was knowledgeable and very supportive,” Murray said. “I immediately felt he would take good care of us.”

A deal was soon closed on a 6 x 12 CL-956 fiber laser cutting system, as well as a 230 Ton X 12’ 230 AF-10 Press Brake.

One major concern that was soon put to rest was whether the inexperienced operators at VMS could work with the CI software.

“We opted for on-site training, and the value of going hands-on with our actual parts was immeasurable,” Murray said. “The team quickly got a good idea of what they can do.”

Windfall in the building

It wasn’t long before VMS grew too big for its tiny area carved out of one of Murray Equipment’s warehouses. A building just across the street became available with 26,000 square feet, and Murray bought it in 2019. As he was viewing the space, he saw a 1961 Cincinnati Shaper Company shear standing in the corner. The current occupant didn’t use it and was going to junk it.

“We had a smaller shear at the time but thought a bigger one might be helpful,” Murray said. “The windfall machine was already able to shear small gauge stainless steel, and now it’s handling up to ½” aluminum, stainless and mild steel.”

The elder shear now stands next to its younger counterparts and is run daily.

“This machine has been around for over 60 years, and it’s still running perfectly,” Murray said. “It’s a testament to the durability of CI products.” And as Rosenberger said, “CI still supports that machine today.”

“The windfall machine was already able to shear small gauge stainless steel, and now it’s handling up to ½” aluminum,

stainless and mild steel.” The elder shear now stands next to its younger counterparts and is run daily. “

Gaining fabrication momentum

Murray acknowledges that the CI equipment is more than he needs at the moment, but he doesn’t see that being the case for long.

“We’re now fabricating parts we had no intention of doing in-house,” Murray said. “And there’s much more to come.”

A few examples of projects he would like to move to VMS in the future include specialized tanks, dry hoppers, pump bases, load out skids, blending skids, bracketry work for automation systems and more.

According to Rosenberger,

“Murray Equipment is taking control of their own destiny. Most shops will buy something because they have a small need. Dan Murray is designing the whole company around these CI machines. He hopes they will lead to more business in the future, and he knows they will help immediately with their vendor bottlenecks.”

Finally, Murray says he appreciates the fact that as his fabrication needs grow, application engineering help is always just a phone call away. In addition, there are 80 service reps nearby to keep all the CI machines operating smoothly – even if they’re six decades old.

If you could use a made-in-the-USA combination of performance and reliability, don’t hesitate. Talk to CI about what you’re dreaming up, and we’ll work with you to make it a reality.